Varmevekslere

Velkommen til Alfa Lavals verden af varmevekslere – betroet af industrien for effektivitet, pålidelighed og bæredygtighed. Fra fjernvarme og datacentre til fødevarer, pharma og tung industri er vores avancerede løsninger designet til at opfylde virksomheders unikke behov, støtte energibesparelser og robust drift, selv under de hårdeste forhold. Vores løsninger hjælper industrier med at reducere energiforbrug, sænke emissioner og udnytte værdifulde ressourcer optimalt.

Udforsk vores fulde sortiment, find den rette teknologi til din proces, og drag fordel af årtiers ekspertise inden for termisk styring.

Vælg den rigtige varmeveksler

Når du overvejer at købe en varmeveksler, bør flere nøglefaktorer styre beslutningsprocessen:

- Vurder de specifikke krav til din applikation, herunder væsketype, flowhastigheder og temperaturområder

- Overvej materialevalg for kompatibilitet og levetid

- Evaluer varmeoverføringseffektivitet og energibesparende funktioner

- Vurder vedligeholdelsesvenlighed og adgang til rengøring

- Undersøg og vælg en anerkendt leverandør for omfattende produktsupport og garanti

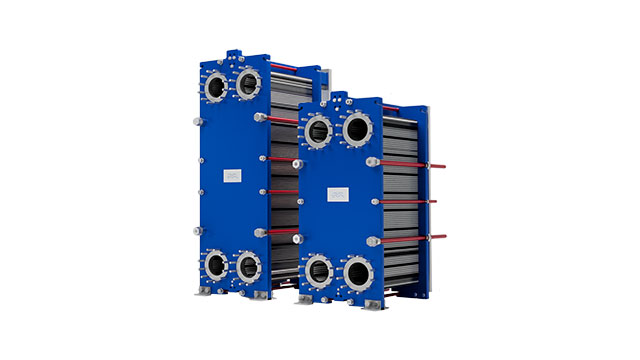

Plade-og-ramme-varmevekslere

Vores brede udvalg af plade-og-ramme-varmevekslere sætter standarden for effektivitet, pålidelighed og servicevenlighed. De fås i forskellige størrelser, er skalerbare og understøtter en bred vifte af industrier.

Pladevarmevekslere med pakninger

Ideele til fjernvarme, varmegenvinding, datacentre og forskellige procesindustrier, vores pladevarmevekslere med pakninger leverer effektiv opvarmning og køling til skalerbare operationer. Løsninger til pålidelig ydeevne i køle- og energisystemer.

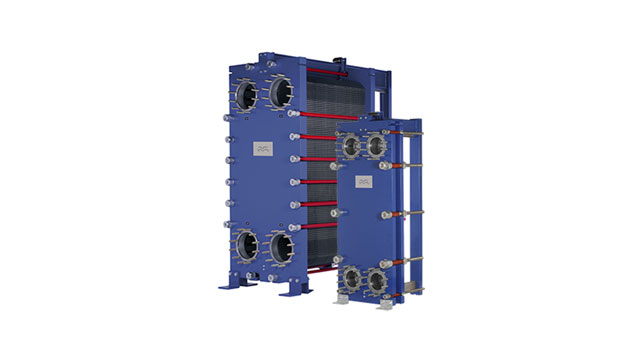

Halvsvejsede pladevarmevekslere

Designet til krævende industrielle miljøer, disse vekslere udmærker sig i køleapplikationer – især med ammoniak og CO₂ – samt højtryksvarmepumper.

Hygiejniske pladevarmevekslere

Perfekt til fødevarer, drikkevarer, mejeri og farmaceutiske processer, Alfa Lavals hygiejniske linje sikrer sikker, ren og energieffektiv varmeoverføring.

WideGap pladevarmevekslere

Effektive varmevekslere til fiberholdige og partikelrige væsker. WideGap er ideel til sukker, bioethanol og papir- & masseindustri og kan konfigureres til opvarmning, køling og væskeudveksling.

Loddede pladevarmevekslere

Kompakte og effektive, vores loddede pladevarmevekslere er ideelle til HVAC, fjernvarme, varmegenvinding og køling. De leverer pålidelig opvarmning og køling til rene væsker, varmepumper og datacentre.

Fusionerede pladevarmevekslere

Fremstillet udelukkende af rustfrit stål med AlfaFusion-teknologi. Disse vekslere tilbyder høj effektivitet og holdbarhed til HVAC, industrielle varmepumper, køling, fjernvarme, tung industri, marine og fødevareapplikationer. AlfaNova fusionerede vekslere er betroet til krævende miljøer.

Gas-til-væske pladevarmevekslere

Specielt designet til kompressor luftkøling, gasbehandling, kraftvarme, gødning, hydraulik og vedvarende energi. Disse vekslere understøtter effektiv termisk styring i avancerede industrielle- og energisektorer.

Svejsede pladevarmevekslere

Svejsede pladevarmevekslere er bygget til alsidige, hårde opgaver, håndterer ekstremt beskidte og aggressive medier samt applikationer med de højeste hygiejnekrav. De er et pålideligt valg for industrier med krævende termiske udfordringer.

Svejsede spiralvarmevekslere

Perfekt til viskøse og udfordrende væsker, spiralvarmevekslere udmærker sig i olieraffinering, papir- & masseindustri, petrokemi, kemikalieproduktion, vegetabilsk olieraffinering og spildevandsbehandling. Deres robuste design gør dem ideelle til sektorer, der håndterer slam, slurry og fiberholdige væsker.

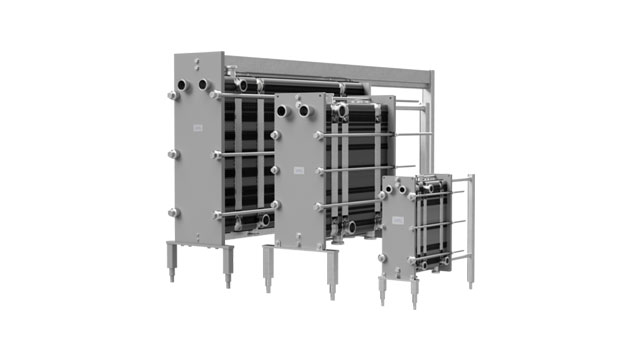

Svejsede plade-og-blok varmevekslere

Compabloc-vekslere er konstrueret til raffinaderier, petrokemi, gødning, olie og gas, koksovngas, aluminiumoxid og biomasse/MSW kraftproduktion. Deres kompakte, svejsede design sikrer høj effektivitet og pålidelighed i de mest krævende industrielle miljøer.

Varmevekslere med trykt kredsløs (PCHE)

PCHE tilbyder overlegen robusthed og exceptionelt høje varmeoverføringshastigheder, hvilket gør dem ideelle til højtryksfordampning i marine brændselsgassystemer, LNG-regasificering, offshore gaskomprimering og kryogene LNG-applikationer. De passer også til højtemperatur energilagring og kulstofopsamling i vedvarende energi.

Luftkølede varmevekslere

Luftkølede varmevekslere er betroet i krævende industrier som petrokemi, strømproduktion, biobrændstoffer, olie & gas og stålproduktion. De er løsningen, når vandkøling ikke er mulig på grund af miljøregler eller begrænsede vandressourcer.

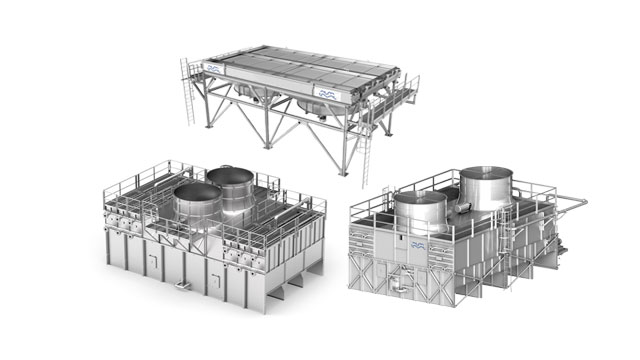

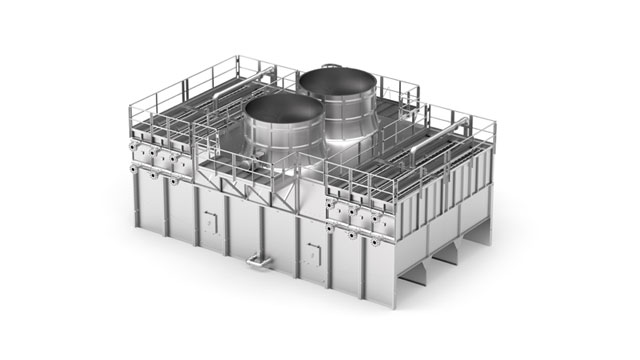

Luftvarmevekslere med våd overflade

Luftvarmevekslere med våd overflade er designet til de største kølebehov, og leverer toppræstation og effektivitet, hvilket gør dem ideelle til faciliteter, hvor maksimal køling er kritisk.

Luftvarmevekslere med finner

Perfekte til mindre kølebehov. Luftvarmevekslere med finner tilbyder effektive og omkostningseffektive løsninger til industrielle processer.

HYAC hybrid luftkølere

Ved at kombinere styrkerne fra vådoverflade- og finneteknologi giver HYAC hybrid luftkølere pålidelig og effektiv køling til et bredt udvalg af industrielle applikationer.

Varmevekslere med skrabet overflade

Varmevekslere med skrabet overflade er essentielle til kontinuerlig termisk behandling af viskøse, klæbrige, krystalliserende eller varmefølsomme produkter. De bruges bredt i fødevareindustrien til supper, saucer, dressinger, puréer, geléer, yoghurt med frugt, hummus, flødeost, smørepålæg, konfekture og proteinprodukter som kød og fisk. Deres robuste design gør dem også velegnede til behandling af fibre og masse i industrielle applikationer.

Contherm® varmevekslere med skrabet overflade

Contherm®-enheder tilbyder avanceret termisk behandling for et bredt spektrum af viskositeter, udmærker sig inden for føde- & drikkevarer (ketchup, mayonnaise, chokoladepålæg), mejeri & protein (flødeost, omeletter, babymad) og kosmetik & pharma (lotioner, shampoo, tandpasta). De håndterer effektivt varmefølsomme, krystalliserende og faseændrende produkter samt dem med partikler, hvilket sikrer optimal ydeevne for klæbrige og udfordrende materialer.

Rørvarmevekslere

Rørvarmevekslere yder i højtryks- og højtemperaturapplikationer i industrier som marine og transport, petrokemi, raffinaderier og kraftproduktion.

Pharma-line skal- og rørvarmevekslere

Vores Pharma-line skal- og rørvarmevekslere er designet til de højeste standarder i farmaceutisk og bioteknologisk industri. De sikrer sikker, hygiejnisk og pålidelig termisk behandling, hvilket gør dem til et betroet valg for producenter af medicin og bioprodukter.

ViscoLine skal- og rørvarmevekslere

ViscoLine varmevekslere leverer effektive termiske løsninger til viskøse fødevarer i fødevare-, drikkevare- og mejerisektoren. Deres robuste design gør dem også velegnede til behandling af massefibre, hvilket sikrer ensartet kvalitet og ydeevne i udfordrende applikationer.

Service til varmevekslere

At holde dine varmevekslere i topform kan gøre en stor forskel for din rentabilitet. Udstyrsproblemer kan ikke kun resultere i uplanlagt nedetid og produktionsstop, men reduceret termisk effektivitet på grund af manglende vedligeholdelse kan også påvirke produktkvaliteten og øge driftsomkostningerne.

Desuden spiller Alfa Lavals varmevekslere en stor rolle i føde- og drikkevarer, stivelse og ethanol samt farmaceutisk industri, og vi ved, at du skal være sikker på deres ydeevne – for at sikre produktionskapacitet samt produktkvalitet og sikkerhed.