Emission reduction

Reducing our carbon emissions from where we are today is one of the largest challenges of our time. It’s going to require completely transforming our global energy system. With a challenge so complex, there can be no simple solution. In fact, it will take a whole range of different solutions to reach the decarbonization targets of the Paris Climate Agreement.

In addition to plate heat exchangers that enable higher efficiency for reduced energy consumption, Alfa Laval’s proven heat transfer and separation technologies are helping customers in a variety of industries to reduce emissions in a variety of ways. We are working with partners in the development of new solutions for carbon capture, and we have also led the way in heat exchangers optimized for environmentally friendly, natural refrigerants. Keep reading to learn more about these solutions as well as our work in related area like contamination-free tap water, sulphur removal and much more.

Decarbonization: a combination of approaches

The challenge of decarbonization is twofold: we must simultaneously support rapidly growing energy demands, while reducing CO2 emissions to meet the goals of the Paris Climate Agreement.

As we see in this chart, a combination of technologies and new fuels are needed to reverse our current course and put us the “Sustainable Development” pathway for meeting the Paris objectives. Reducing the world’s emissions requires investment in energy efficiency and renewables, as well as technologies such as carbon capture utilization and storage (CCU/S).

Alfa Laval has already partnered with numerous customers to support their emission reduction goals. Contact us today to learn how we can help your business.

Watt’s it worth?

What is the true potential of more efficient plate heat exchanger technologies? In global terms, the potential energy savings are amazing. By comparing the impact of energy in our major cities, or even in our own homes, you begin to see what is actually possible.

Every year, newly installed Alfa Laval plate heat exchangers enable our customers to save 50GW of energy. That’s the same amount of energy that it takes to annually heat 10 million European homes.

But saving energy only tells half the story. That 50GW also translates to a 25-million-tonne reduction in global CO2 emissions, or what’s emitted every year by the city of Paris.

And all that is just new heat exchanger installations. Imagine the exponential impact of millions of efficient plate heat exchangers installed around the world as they multiply every year. You start to get a real sense of our potential to accelerate global sustainability.

Curious what it can mean for your processes? Contact us today, and our experts will be in touch!

Emissions savings in numerous applications

Alfa Laval’s plate heat exchanger and separation technology enable emission reduction in a wide range of applications. Want to learn how we can support you to reduce emissions in your operations? Select your application from the list below.

Carbon capture, utilization & storage

You may have heard of carbon capture, utilization and storage (CCU/S), but did you realize the technologies to enable it have been around for decades? With limited options for decarbonization in sectors like oil & gas, power, refinery, petrochemicals and cement industry, CCU/S will be fundamental for the future of the energy market. Discover our portfolio of heat transfer equipment designed to maximize the efficiency of carbon capture.

Tap water

Alfa Laval understands that in today’s tap and warm water heating applications, safety is just as important as cost-efficiency and performance. Drawing on our deep knowledge of plate heat exchanger technology, we have developed innovative solutions that offer the best assurance of safe water systems along with improved efficiency to minimize energy consumption and reduce contamination. Contact us today to learn how we can support your needs in designing the safest, most sustainable tap water solutions.

Natural refrigerants

The heating and cooling market is rapidly moving away from traditional refrigerants in favour of those with lower global warming potential (GWP), in particular natural refrigerants like ammonia, CO2 and hydrocarbons. Alfa Laval has led the way in the development of solutions optimized for tomorrow’s refrigerants. We can work with you to identify the right technology to ensure you get maximum efficiency with a minimized ref charge for your application.

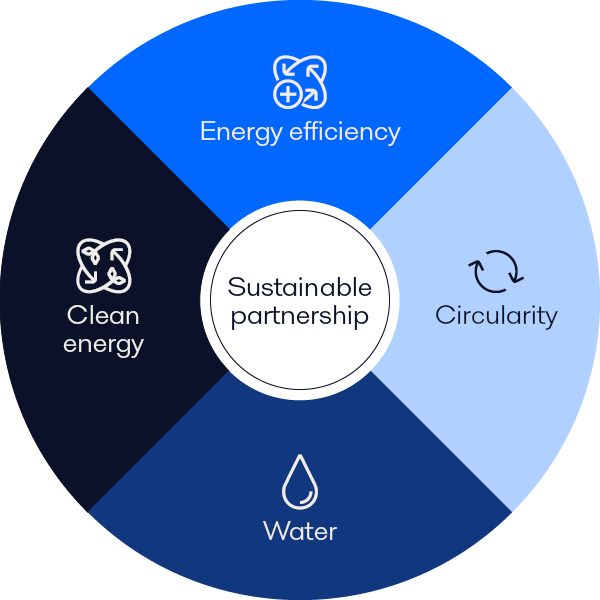

Energieffektivitet

Ren energi

Et bæredygtigt partnerskab

Kontakt os for mere information

Kontakt os i dag for mere information om vores bæredygtige løsninger