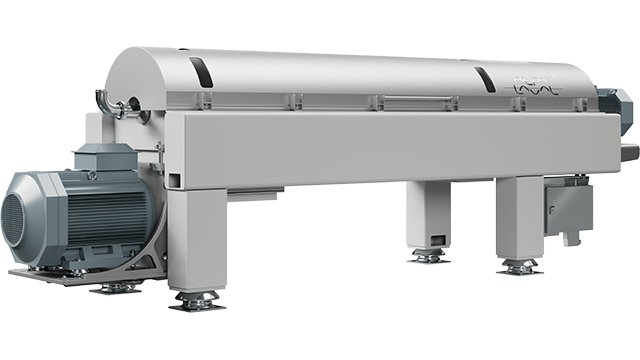

ALDEC G3

Alfa Laval ALDEC G3-dekantercentrifuger er den nyeste generation af slamafvandingsudstyr til kommunale og industrielle spildevandsrensningsanlæg, der er designet til at sætte en betydeligt højere standard for både procesydelse og miljøpåvirkning i slamfortykning og afvanding.

Banebrydende dekanter, der sætter nye standarder for ydeevne

- Lavere strømforbrug (hvilket også i høj grad reducerer CO2-udledningen)

- 10% boost i forarbejdningskapacitet - eller tørrere kage

- Reduktion af livscyklusomkostninger

- Mere effektiv håndtering af slam

- Bedre procesovervågning og -kontrol

Den avancerede serie af slamdekantercentrifuger bidrager væsentligt til et bæredygtigt miljø. Det innovative design leverer toppræstationer til enhver tid, samtidig med at det samlede strømforbrug reduceres med op til 40%. Denne betydelige forbedring resulterer i store reduktioner i CO2-emissioner.

Et nyt sæt af innovative parametre

Alfa Lavals enestående decantercentrifugeteknologi har ført til en række banebrydende innovationer, alt baseret på gennemprøvet teknologi kendt for sin pålidelighed. Sammen sikrer disse en unik kombination af bedre ydelse og lavere energiforbrug, hvilket resulterer i lavere driftsomkostninger end nogensinde før.

ALDEC G3-dekanteren er bygget op omkring Slimline-designet - et gennembrud inden for dekantercentrifugerydelse og -kapaciteter. Den mindre transportørdiameter giver plads til mere væske i dammen og tillader højere kuglevægstryk, hvilket resulterer i enten tørre kage eller ved at bruge mindre polymer.

Patenterede Alfa Laval-Power plader reducerer også effektivt strømforbruget til ALDEC G3-dekantercentrifuger, hvilket fører store omkostningsbesparelser.

Every ALDEC G3 decanter is equipped with a PLUS control package as standard, pre-installed and tested in conjunction with each particular unit. The combination of PLUS controls with the ALDEC G3 ensures the best possible performance, keeping costs for installation, commissioning, operation and maintenance to a minimum.

Sludge dewatering centrifuge - feature highlights

- Power plates/tubes and slimline conveyor design

- Critical components made of wear-resistant material

- Fully open feed zone for improved separation 360° solids discharge to avoid blocking

- Baffle disc provides higher capacity and drier cake solids

- Steep or shallow cone configuration for effective separation of any type of slurry

- Selection of conveyor designs available for use with different types of slurry

- Different forms of wear protection for conveyor flights, to suit any processing requirements

- Complete, fully enclosed cleaning-in-place (CIP)

Sådan fungerer det

Separeringen finder sted i en vandret cylindrisk kugle udstyret med en indvendig snegle-transportør. ”Feed'et” kommer ind i kuglen gennem et stationært indløbsrør og ind til en indløbsfordeler. Den centrifugalkraft der skabes af kuglens rotation fører derefter til sedimentering af de tunge partikler på kuglens væg og væskedelen ind mod midten.

Snegle-transportør roterer i samme retning som kuglen, dog lidt langsommere, denne forskel gør at de tunge partikler transporteres mod kuglens koniske ende. Kagen (de tunge partikler) skubbes ud af kuglen gennem de faste udløbsåbninger i kugle-kappen. Separeringen finder sted over hele længden af kuglens cylindriske del, og den væske delen flyder ud kuglen ved gennem power tubes i enden af kuglen.

Ta' din ALDEC G3 dekanter på næste niveau

Overvejer du at opgradere din ALDEC G3 VecFlow™ transportør?

Evaluering af dekanter-centrifugers ydeevne

Opnå en optimering af dekanter-centrifugering og omkostningsbesparelser med Alfa Lavals evaluering af ydeevnen, hvor vores globale service- og supporteksperter hjælper dig med at få mest muligt ud af dit udstyr.

Skær ned på driftsomkostningerne med Alfa Lavals IoT-services

Alfa Lavals IoT-services er en række digitale tjenester, der sigter mod at reducere driftsomkostningerne og maksimere driftssikkerheden i spildevandsanlæg.

Lad os hjælpe dig

With industry-leading wastewater technology and expertise based on the experience from thousands of Alfa Laval decanter centrifuge installations, we can help analyse your unique situation and select the optimal equipment model, configuration and services for your needs and budget.

Vores kunder:

Løsninger til den cirkulære økonomi

Flere og flere spildevandbehandlingsanlæg opdager fordelene ved en cirkulær, holistisk tilgang til spildevandsbehandling. Omkostningsbesparelser, reduceret miljøpåvirkning og nye indtægtsstrømme fra genvundne ressourcer for at nævne nogle få. Ethvert spildevandbehandlingsanlæg er unikt og har sine egne udfordringer og muligheder. Med vores ekspertise inden for forarbejdning og vores brede produktsortiment, kan vi understøtte dit skifte til et cirkulært ressource-flow. Uanset om du er entreprenør, konstruktør eller anlægsoperatør, kan vi hjælpe dig med at finde den rigtige løsning til dit specifikke projekt.