Beer and beverage concentration

Alfa Laval solutions for beer and beverage concentration remove water from beer, wine and cider after fermentation. Using a high-pressure, low-temperature reverse-osmosis process produces a high-quality concentrate. The beverage concentrate once rehydrated for onward sale has the same taste, aroma and alcohol content as the original product. A concentrate-based supply chain cuts packaging and shipping costs. It simplifies delivery logistics and reduces the environmental impact of distribution

Reduce your logistics costs and improve your sustainability profile with high-quality beer and beverage concentrates

- Reduced transport costs due to reduced shipping volumes with beer and beverage concentrates

- Lower overall supply chain costs due to reduced volumes of beer and beverage concentrate to package, store and transport

- Reduced storage requirements at the point of sale, such as bars and restaurants

- Upon rehydration of the concentrate, beer has the same taste, aroma and alcohol content as the original product

Get end-to-end solutions for your beverage concentration needs from Alfa Laval Beer and beverage concentration systems. These compact, reliable and energy-efficient solutions increase the efficiency of production, transportation, storage and draft dispensing at bulk packaging facilities and at the point of sale. This translates into higher productivity and yield, lower capital costs and more sustainable distribution.

Reduce bulk transportation costs by up to 80% while reducing the carbon footprint of your supply chain with Alfa Laval beer and beverage concentration systems.

Sensory example: freshly reconstituted

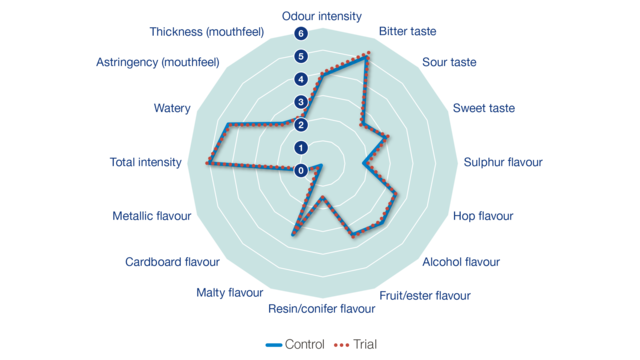

Comparison of fresh beer and reconstituted Revos beer concentrate

Procedure

- Fresh reconstituted lager was subjected to detailed descriptive sensory panel testing

- Scores were averaged over a large group of panellists

Results

Sensory panel tests reveal minimal to no differences between the control (fresh beer) and the trial (reconstituted beer)

Continuous concentration process, hygienic design

The Alfa Laval beer and beverage concentration systems feature proprietary filters with an ultra-tight membrane pore structure that allows water to pass easily through while retaining the alcohol, aromas, proteins and sugars in the concentrate. The membrane filters withstand high pressures – enabling higher concentration factors – and eliminate dead zones during Cleaning-in-Place (CIP). This translates into more uptime and higher standards of hygienic design with full membrane cleanability.

Space-saving, energy-saving systems

Choosing Alfa Laval’s reverse osmosis concentration technology results in a space-saving system with significantly lower capital costs and lower energy requirements than other technologies, such as freeze concentration or forward osmosis technologies. Moreover, Alfa Laval beer and beverage concentration systems do not require feed degassing, thereby preventing flavour loss.

Higher throughput, lower costs

Parameter optimization for each beverage maximizes throughput and significantly reduces product losses while retaining the product’s flavour profile.

Alfa Laval Revos applications

Bulk transport

Save €5–15 per hl on tanker transport

Re-draft system

Re-draft cellar: Allow bars to serve beer or other beverages from kegs of concentrate

Re-draft mobile: Provide a compact serving solution for seasonal venues

How it works

Alfa Laval beer and beverage concentration systems use a high-pressure, low-temperature reverse osmosis process. Operating at pressures above 120 bar (1,700 psi) achieves a higher concentration factor, thereby reducing shipping volumes and costs.

To achieve a high-quality concentrate, the product flows through a proprietary membrane filter. The membrane allows water to pass through it, due to pore size and polarity, but prevents the passage of proteins, sugars, aromas and alcohol. Water flows through the membrane, while the pressurized beverage becomes more concentrated as it flows along the membrane.

Afprøv Alfa Laval Revos koncentrationssystem. Send otte fad af din øl eller anden drikkevare til et af Alfa Lavals to teststeder (enten i USA eller Danmark), og deltag i en test og præstationsvurdering på stedet.

Du kan også leje og teste en enhed på kommerciel skala for at vurdere koncentratgennemstrømning og produktkvalitet på dit forretningssted.

Spørgsmål og svar om Revos-koncentrationssystem

Find svar på de oftest stillede spørgsmål om Revos-ølkoncentrationssystemet her.

Bekæmpelse af kulstofemissioner - Lær mere fra vores white paper

Hvordan kan bryggerier og drikkevarefabrikker reducere deres CO2-aftryk, og samtidig gøre driften mere effektiv? Reduktion af direkte og indirekte emissioner spiller en vigtig rolle – fra indkøb af råvarer, elektricitet og fremstilling til emballage, materialer og distribution. Dette white paper har fokus på omvendt osmose (RO) membranfiltrering af øl- og drikkevarekoncentration, som er en omkostningseffektiv måde for producenter at reducere CO2-aftrykket i deres forsyningskæder.

Service

Service til fødevaresystemer

Alfa Lavals service til fødevaresystemer hjælper med at øge ydeevnen for dine fødevaresystemer ved at maksimere dine processers ydeevne. Dette giver dig mulighed for:

- Løbende at forbedre din drift for at kunne opnå konkurrencefordele

- Fokusere på oppetid, optimering og tilgængelighed

- At maksimere investeringsafkastet gennem hele dine fødevaresystemers livscyklus