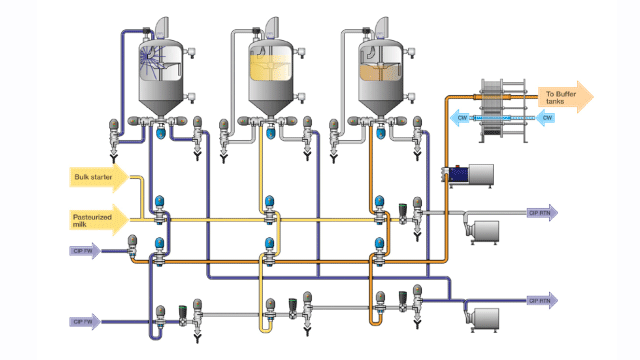

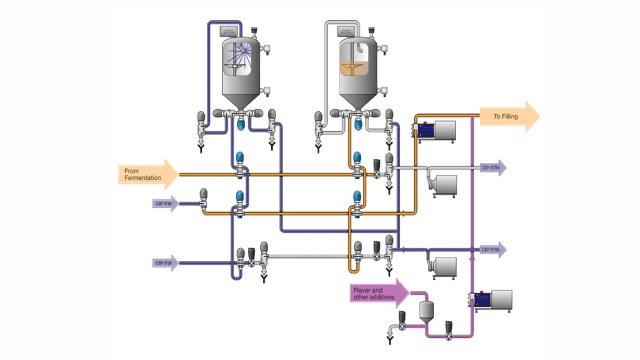

Fermentering

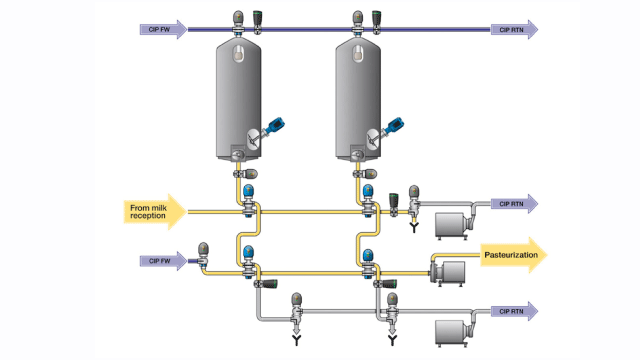

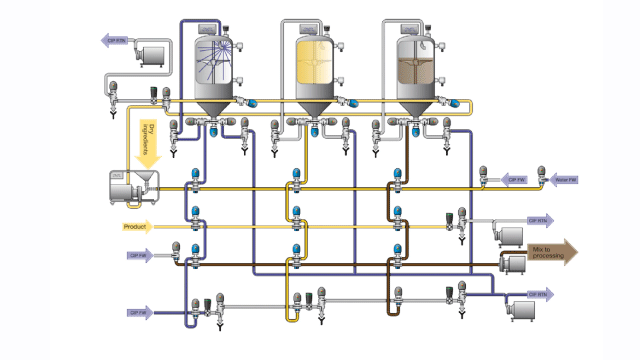

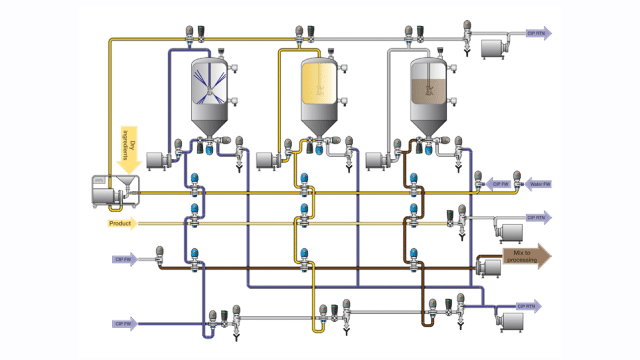

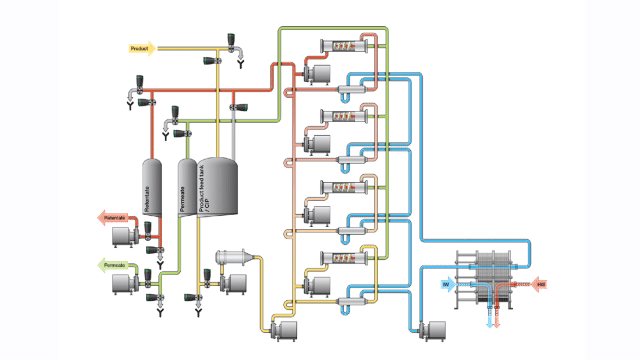

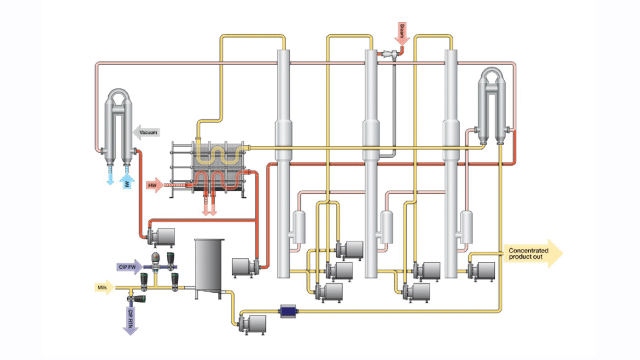

At få mest ud af råvarer er essentielt i produktion af kulturer såvel som friske og lagrede oste. Vigtige aspekter inkluderer opnåelse af maksimal effektivitet i kontinuerlig batch-produktion og vedligeholdelse af procesforhold.

Innovativt Alfa Laval-udstyr

Alfa Laval SRU-loberotorpumpe

• Pumpefunktion med lav forskydningsspænding opretholder produktets integritet

• Bredt udvalg af modeller og ekstraudstyr sikrer optimale anvendelsesmuligheder

• Hygiejnisk design

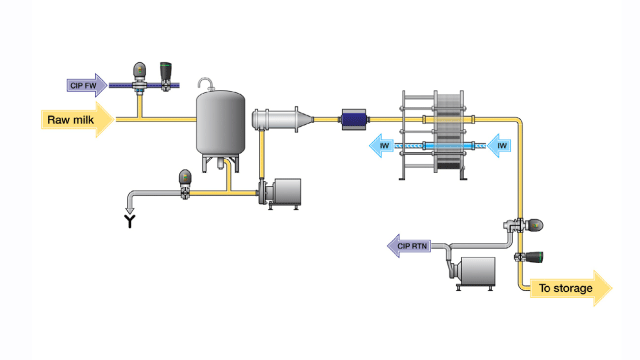

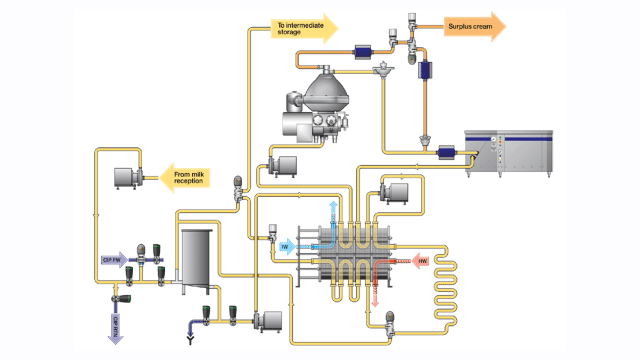

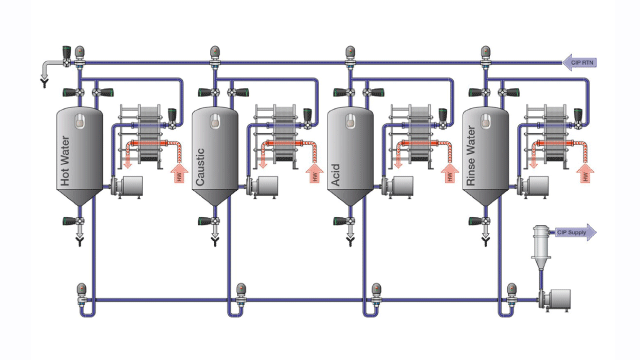

Alfa Laval FrontLine varmeveksler

• Ideel til hygiejniske processer, der kræver optimal ydelse, nænsom produktbehandling, lange driftstider og uovertruffen renseevne

• Nem at servicere, hvilket resulterer i mere oppetid og lavere omkostninger

Optimér mejeriprocesser

OLEŠNICE CHEESE PLANT, CZECH REPUBLIC, With reliability, health and safety as their prime concerns,the dairy management decided to replace the old pasteurizers with the new Alfa Laval FrontLine Heat Exchanger with Gemini double wall plates. “Owing to our limited space, it was a bit of a struggle to get the heat exchangers into position. But since then, we haven’t had a single problem with them,” says Šlégr. According to Šlégr, the new pasteurizers have already passed a short and unintended endurance test, when pressure in the pipes briefly reached 6 bar. “The bearings in the old unit would already have blown,” he believes. The two new plate heat exchangers are scheduled to run 365 days a year, 5 a.m. to 6 p.m., with different temperatures for each end product: 98°C for milk and 74°C for cheese.