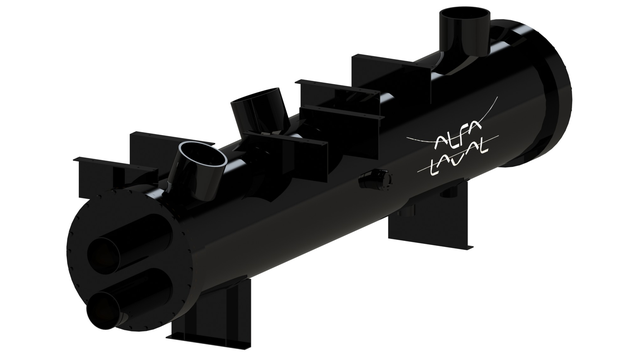

FEV HP

The Alfa Laval FEV is a high-performance flooded evaporator for air conditioning and industrial refrigeration systems. The flooded evaporators are utilized when operation with closer temperature approaches than that provided by dry expansion evaporators is required. Evaporation temperatures range from 0°C to +10°C. The Alfa Laval FEV has been optimized for R134a and R1234ze refrigerants at low pressure. Capacity range 250 – 5000 kW. PED/CE, ASME and SELO pressure vessel codes are available.

Applications

Flooded evaporators for air conditioning and process cooling applications where the primary driving force is energy efficiency improvement, especially at part load conditions.

This demand is being driven by different regional energy efficiency standards such as ASHRAE 90.1 or Eurovent chillers certification program.

Technology

The Alfa Laval FEV evaporator series has been designed for use with HFC 134a and HFO1234ze but it can also be utilized for other HFCs as well as natural refrigerants such as propane. The latest high performance boiling tubes ensure that the Alfa Laval FEV series has the highest performance available in the market.The compact design meets refrigerant charge guidelines such as those in California Title 24 Energy Efficiency Standards for Residential and Non Residental Buildings, which are gradually imposing limitations to the refrigerant charge for acceptable cooling systems. A value of 2.7 lb/ton (0.35 kg/kW) is becoming a new standard.

Design features

- Standard models and custom designs are available

- Two standard product lines: oil-free centrifugal compressors and screw compressors

- High efficiency enhanced tubes for pool boiling

- Low refrigerant operating charge

- Internal separation device to prevent liquid carryover to the compressor

- Models for use with screw compressors include ports for return oil

Benefits

- Compact design vs equivalent products in the market

- Suitable for high efficiency demand with COP up to 6

- Suitable for oil-free centrifugal compressors and screw compressors

Sådan fungerer det

Liquid refrigerant coming from the condenser enters the evaporator through a connection located underneath the shell. A distribution plate helps the refrigerant to flood the refrigerant circuit up to the highest row of tubes – normally placed at half of the shell height – avoiding preferential paths.

When the refrigerant makes contact with the tubes, it is boiling. The evaporation process is completed as refrigerant vapour, including some liquid residual, ascends towards the compressor. The upper distribution plate blocks any remaining liquid droplets, thereby fully protecting the compressor.