BTUX

The Alfa Laval BTUX separation system has been specifically developed to ensure optimum separation and concentration efficiency in biotechnological applications.

The BTUX separators take advantage of the fact that the slurry of concentrated solids is pseudo-plastic and flows easily in the bowl against the centrifugal force. This means that the recovered solids can be obtained with a low demand on energy in a closed system under pressure. Therefore, the hygienic conditions are very good, further improved by a full-speed CIP procedure.

Unique Vortex nozzle design

Like the FEUX and MBUX separator models, the BTUX separator bowl is equipped with Alfa Laval´s unique vortex nozzles, which offers performance unmatched by conventional nozzle centrifuges. With the self regulating vortex nozzles the concentration of discharged solids phase can be kept at a high and even level irrespective of fluctuations in the feed flow or feed concentration. The centrifuge can thus be operated closer to the clogging point without increasing the risk of clogging.

The BTUX separator system is designed for automatic ejection of washed-out solids during the cleaning cycle, which makes it particularly suitable for process lines equipped with automated cleaning-in-place (CIP).

A complete separation system

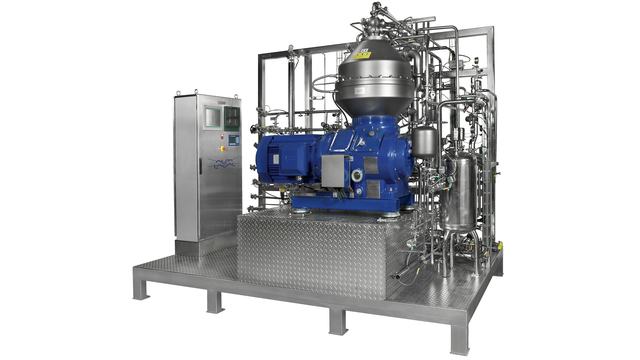

The BTUX is available in different sizes covering a wide range of process demands. A complete BTUX separation system consists of the BTUX separator, electric motor, solids cyclone, switch gear panel and starter, control panel, valve cluster, flow meter, sight glasses, flexible connections and other related equipment.

Benefits

- Self-regulating vortex nozzles for optimal concentrate dryness and minimum clogging risk

- Sterilizable and high g-force

- Hygienic design

Sådan fungerer det

BTUX separators exploit the fact that the slurry of concentrated solids is pseudo-plastic and flows easily in the bowl against the centrifugal force. This means that the recovered solids can be obtained using relatively little energy in a closed system under pressure.

Separation takes place in the disc type bowl which is equipped with concentrate tubes and vortex nozzles. The heavy solids phase is moved outwards by the centrifugal force in to the solids pockets at the bowl periphery and from there through concentrate tubes and internal vortex nozzles into the paring tube chamber, where the concentrate is skimmed off by the paring tube and discharged under pressure. The clarified liquid phase is displaced towards to the centre through the disc stack. This phase is then discharged under pressure by means of a built in paring disc.

The valve slide under the bowl bottom opens the discharge valves momentarily, permitting the ejections of solids.

Self-regulating vortex nozzles

The unique vortex nozzles automatically compensate for variations in the feed flow rate or feed solids concentration to ensure a constant concentration of the discharge solids phase.

The self-regulating feature is based on the relationship be-tween the viscosity of the liquid entering the vortex chamber and the effect of its rotation velocity on the pressure drop.

The concentrate enters the chamber of the vortex nozzle tangentially at the periphery, forms a whirl in the vortex chamber and leaves through a hole in the centre of the nozzle. The inlet and outlet pressure of the liquid is similar to normal pressure drops. In principle, these pressure drops are not affected by the viscosity of the concentrate. The pressure drop created by the spin, or whirl, of the concentrate in the vortex chamber is high, if the rotation velocity is high, and low at low velocities.