The real deal: improving efficiency in the brewing of craft beers

When an independent brewery in Northern Europe was looking to replace the heat exchanger it used for cooling wort – a central part of brewing operations – they chose an H4 from Alfa Laval’s Hygienic line. They are now producing their signature wild yeast beers with higher hygiene and greater efficiency than ever

DATE 2025-01-24

Popularity of craft beers

Since beginning production in 2012, this brewery has focused primarily on beers fermented with wild yeast and bacteria. They all contain 100% natural ingredients; many are organic and the majority are also vegan. About 30% of the brewery’s output is exported to Japan, Italy and Spain, while the remaining 70% is sold on the home market.

“The brewing industry suffered a downturn in demand during the pandemic and has yet to fully recover,” says the brewer, “but we are gradually getting back to pre-pandemic figures. The good news is that the current trend for naturally produced, authentic and interesting products is as relevant to beer as it is to other areas of life. People want the real deal, and that’s what we give them.”

Hygiene is the top priority

In all beer brewing operations, hygiene is the number one priority. “The reason is simple,” explains the brewer, “if the beer gets contaminated, it can’t be used, which means time, money and product all go to waste. That’s why we take every possible measure to avoid contamination by, for example, cleaning the equipment carefully between production runs and working – as far as possible – with a closed system to prevent human contact with the product.”

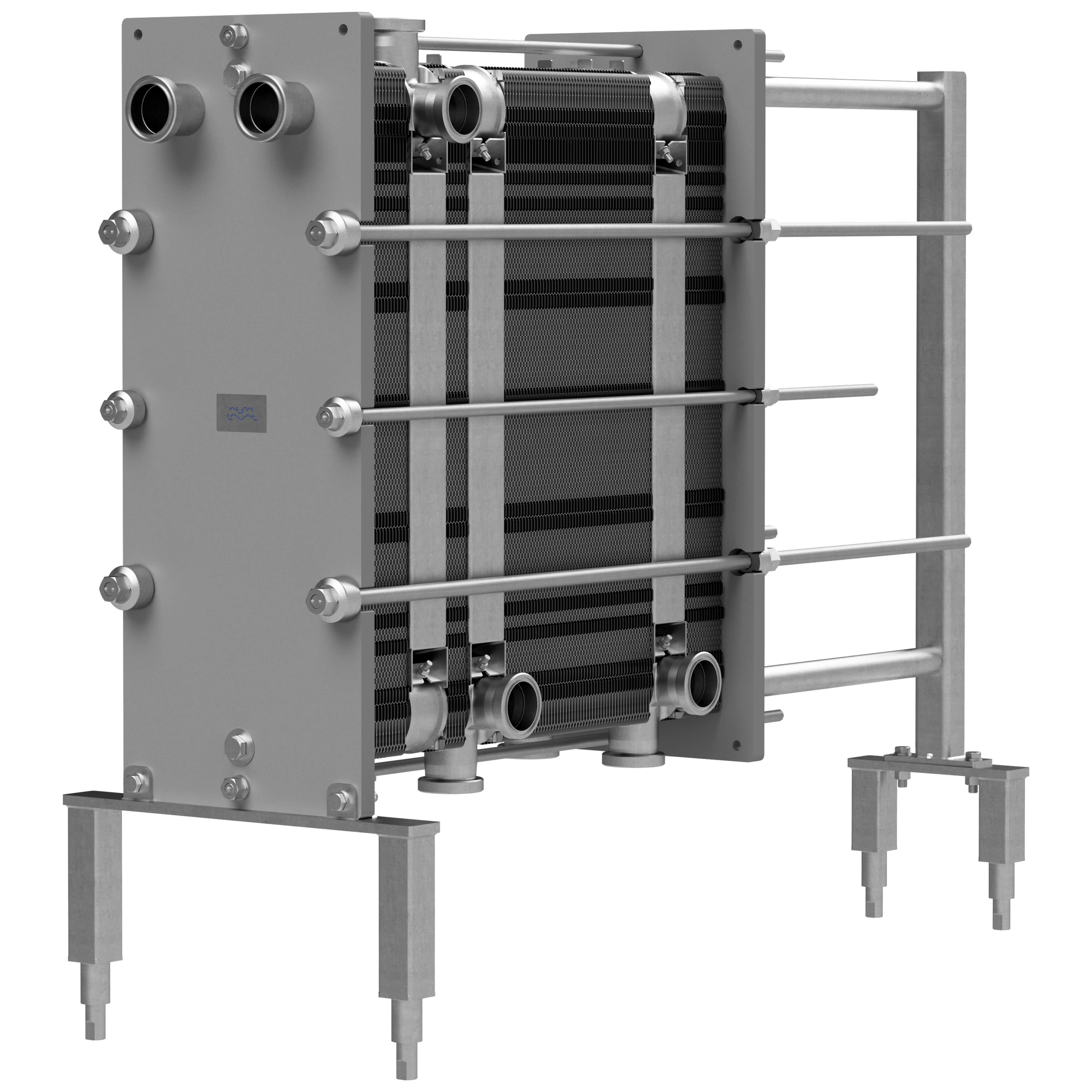

When the brewery started studying its options for a new heat exchanger, the hygiene factor was a given, but it was not the only one. They were also looking to improve performance. “We had been using the same heat exchanger for a decade and were not completely satisfied with its cooling efficiency,” explains the brewer. “Moreover, our energy consumption was high, especially during summer months when the cooling water entering the system is warmer to begin with. That meant the heat exchanger had to be run at low speed which slowed operations down. We hoped to find a new one that would help us address these issues.”

Meeting and exceeding expectations

As the range name suggests, hygiene is key in the design of Alfa Laval H4. After using the new heat exchanger for over a year, the brewer confirms, “The plates are indeed very easy to clean! In fact, we haven’t had any issues with cleaning or contamination since we started using it.” When it comes to the other criteria, the brewery’s expectations have actually been exceeded:

The new equipment has reduced wort cooling time by 25%, and significantly reduced water consumption. We’ve also enjoyed major energy savings since the temperature of the outgoing water is higher, and therefore requires less energy to prepare it for brewing.

According to Alfa Laval, these benefits are also thanks to the new plate design which optimizes flow distribution and improves heat transfer efficiency, enabling a reduction in the consumption of water, cleaning media and energy.

Quality products and a helpful team

Looking ahead, the brewer hopes to be able to invest in other processing equipment from Alfa Laval in the years to come. “High quality products are of course the main reason for choosing Alfa Laval,” he says, “but other things matter too. For example, having good contact with the people and being able to rely on them for rapid technical support when needed. The Alfa Laval team has been extremely helpful every step of the way – something we really value as a small company.”

Fremhævede teknologier

Uptime

Reduced wort cooling time by 25%

Energy savings

Major energy savings

Water savings

Significantly reduced water consumption