2015-04-16 Product News

“On the way to zero discharge” is one of the themes presented by Alfa Laval at Achema 2015

At the Achema exhibition in Frankfurt, Germany, June 15-19, Alfa Laval presents a number of new technologies that help process industries reduce their environmental footprint from water and waste streams by maximizing reuse of water, by turning waste to value and by minimizing energy consumption and waste.

Most industrial processes consume lots of water – a scarce resource. They also generate waste that needs to be treated in order to meet tough requirements, keep the license to operate and perhaps even extend capacity. On the positive side, waste streams often contain valuable resources from the main process, which can be recycled. Alfa Laval has considerably expanded its portfolio and now offers a wide variety of technologies for industrial water and waste treatment.

On-site wastewater treatment

Industrial wastewater varies considerably in specification. Often it is not accepted by the municipal wastewater treatment plant so either pre-treatment or complete on-site treatment is needed.

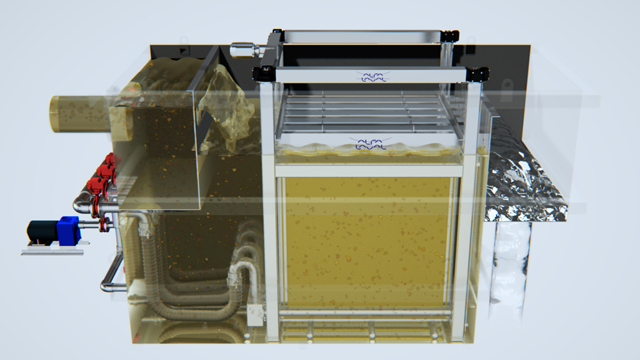

Alfa Laval offers two on-site biological wastewater treatment and filtration systems that help fulfil stringent effluent requirements. The AS-H Sequencing Batch Reactor (SBR) with a patented floating decanter is a good choice for secondary biological treatment. The all-in-one Membrane bioreactor (MBR) system, based on the company’s patented Hollow sheet technology, performs secondary and tertiary treatment as well as final polishing. Both systems have all processes in the same tank and are characterized by high efficiency, small foot print and simple operation.

For some types of industrial wastewater e.g. petrochemicals, chemicals and pharmaceuticals evaporation of anaerobic effluent and crystallization of salty effluents using Alfa Laval AlfaVap and WideGap systems is a good solution.

Wastewater – an untapped water resource

A world population growing by 75 million every year combined with disappearing natural water resource is a serious challenge. By 2025 two billion people will be without access to fresh water. So every litre saved - or recovered for reuse - in process industries is welcome. In fact, wastewater is an untapped water resource that more and more companies want to explore.

Alfa Laval offers several treatment methods that can make water reuse happen. The company’s Membrane bioreactor system and the AS-H Iso-Disc® Cloth Media Filter for tertiary filtration both produce very high quality effluent that it is ideal for water reuse.

The reclaimed water can be reused in many ways: As industrial process water, for cleaning, cooling towers, irrigation of crops, golf courses, recreation lakes, wetlands or ground water recharge. If MBR and Iso-Disc is followed by final polishing with ultrafiltration, nano filtration, reverse osmosis, active coal, ozone, chlorine or combinations of these, reclaimed wastewater can even be used for potable water.

Waste-to-value - Recover valuable products

Valuable products are normally lost in waste streams. Alfa Laval can help convert cost to profit and offer various solutions to recover products of value that can be recycled or sold.

A good example is recovery of oily waste streams like e.g. slop oil that can be converted into a high value hydrocarbon using decanters and high-speed separators.

Waste dewatering - Reduce the amount of waste for disposal by up to 90%

The liquid content of sludge from on-site waterworks, industrial wastewater treatment and waste from operations has a high impact on disposal costs. Alfa Laval offers numerous technologies, including new gravity and press equipment, to effectively separate off the liquid phases and achieve a high level of dry solids content, significantly reducing the amount of waste - and costs for transport, disposal and drying.

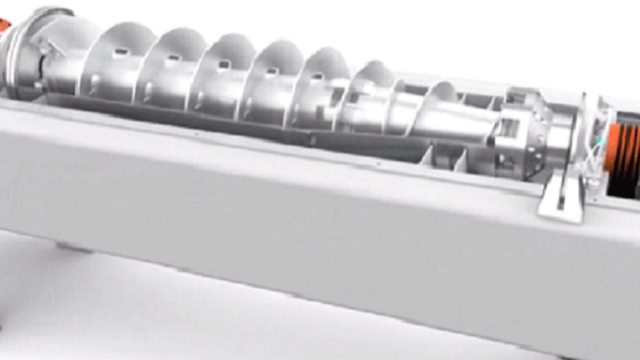

Alfa Laval sludge thickening equipment includes ALDRUM drum thickeners, ALDEC decanters and Alfa Laval AS-H belt thickeners. For energy-efficient dewatering of sludge and separation of liquid and products from other waste streams four Alfa Laval options are now available: ALDEC decanters, screw presses, AS-H belt presses and AS-H plate presses. Some of these technologies can also be used for mud dewatering (biological and non-biological), mine tailings, pond clean-up and dredging.

Thermal sludge treatment – a short cut to cost saving, heat recovery, Class A compost and biogas

Pre-heating of wastewater sludge using Alfa Laval spiral and tube-in-tube heat exchangers prior to dewatering can cut costs and provide an opportunity for heat recovery. Alfa Laval thermal equipment can also be used for sludge digestion to produce biogas and for sludge hydrolysis and pasteurization to meet even the most stringent environmental legislation and obtain class A or B sludge quality suitable for reuse as compost or fertilizer. For some types of industrial waste, e.g. pharmaceutical, pasteurization of wastewater sludge is a must.

Discover more at Achema

Visitors to Achema will have the opportunity to hear much more about the new industrial water and waste treatment solutions from the company’s experts at Alfa Laval’s stand D4 in Hall 4.0, where a number of products are on display. Alfa Laval will also present these topics at various occasions:

Press breakfast Tuesday June 16 from 8:30-9:30 at Alfa Lavals stand D4 in Hall 4.0

Register via email to rolf.lindenberg@alfalaval.com

At the Achema conference Alfa Laval will present two related lectures, among others:

- Tuesday June 16 at 13:00 Hall CMF Room: Harmonie 2: "Meeting the challenges: Membrane processes for water recovery and process intensification"

- Wed. June 17 at 12:30 Hall CMF Room: Harmonie 2: "Full-scale Sequencing Batch Reactor Design and Operation for Treatment of Target Compounds from a Pharmaceutical Facility"

Speaker’s corner presentations at Alfa Laval’s stand D4 in Hall 4.0

- Monday June 15 at 14.00 – “Water and waste treatment. Converting a cost centre into a profit centre.”

- Tuesday June 16 at 13.00 – “Reuse your wastewater – an untapped water resource. Water reclaimed using Alfa Laval filtration technologies (MBR, ultrafiltration and Iso-Disc filtration) can be used for a number of purposes.”

- Wednesday June 17 at 11.00 – “Biological wastewater treatment and filtration (SBR, Iso-Disc, MBR)”.

- Thursday June 18 at 10.00 – “Minimizing your waste for disposal by efficient on-site sludge thickening and dewatering. A comparison of the various technologies (belt thickener, drum thickener, decanter, belt press and plate press).”

For more information, see www.alfalavala.com/achema2015

Tags

Alle